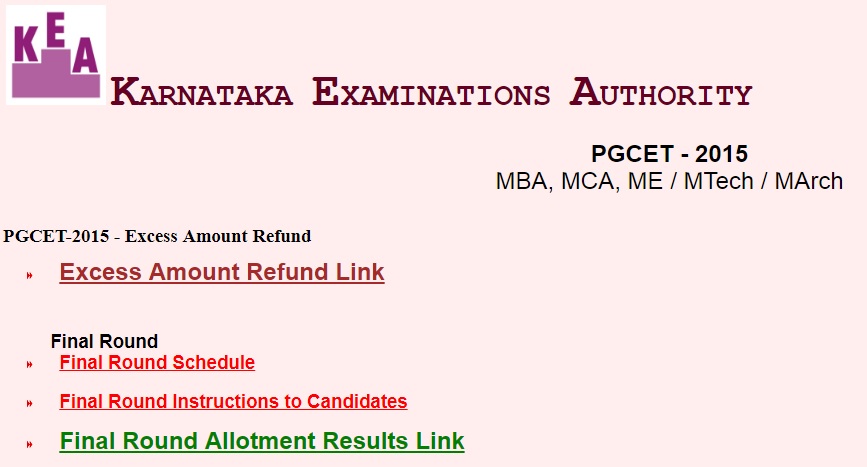

Karnataka Examinations Authority PGCET Textile Technology Question Paper : kea.kar.nic.in

Name of the Organisation : Karnataka Examinations Authority

Name of the Exam : Common Entrance Test

Subject: Textile Technology

Year : 2015

Document Type : Question Paper

Website : https://cetonline.karnataka.gov.in/kea/indexnew

Download Model Question Paper :

Textile Technology 2010 : https://www.pdfquestion.in/uploads/13539-Textile2010.pdf

Textile Technology 2013 : https://www.pdfquestion.in/uploads/13539-Textile2013.pdf

Textile Technology 2014 : https://www.pdfquestion.in/uploads/13539-Textile2014.pdf

KEA PGCET Textile Technology Question Paper

Time: 2 Hours

Max. Marks: 100

Read the following instructions before answering the test :

** Write / Darken the particulars of your identity, Test Seat Number and afix your signature on the OMR Response Sheet before the start of the ” test.

Related : Karnataka Examinations Authority PGCET Electrical Sciences Question Paper : www.pdfquestion.in/13536.html

** All Questions have multiple choices of answers, of which only one is correct.

** Mark the correct answer by completely darkening only one oval against the Question number using Black Ink Ball Point pen only.

** There will be no negative evaluation with regard to wrong answers.

** Marks will not be awarded if multiple answers are given.

** Do not make any stray mark on the OMR Response sheet.

** For rough work, use blank page on the question paper.

** Taking the question paper out of the test hall is permitted only after then full duration of the test.

** Use of only non-programmable calculator is permitted.

** Start Answering Only At The Specified Time When The Invigilator Gives Instructions.

Marks Distribution :

PART – I 50 Questions : 50 x 1 = 50 Marks

PART – II 25 Questions: 25 x 2 = 50 Marks

Total Marks : 100

1. The measure of stiffness associated with handle is known as

(a) Bending Length

(b) Bending Modulus

(c) Flexural Rigidity

(d) Toughness

2. Abrasion is just one aspect of

(a)Pilling

(b) Wear

(c) Pilling and Wear

(d) Creasing

3. One of the objects of doubling is

(a) To reduce the irregularity

(b) To reduce neps

(c) To increase crease recovery

(d) To reduce slubs

4. The process of removing loose hairy fibres projecting from the surface of the cloth is known as

(a) Sizing

(b) Desizing

(c) Singeing

(d) Waxing

5. Hydrogen peroxide bleaching is carried out at a temperature of

(a) 80-85 degree centigrade

(b) 140 degree centigrade

(c) 200 degree centigrade

(d) 180 degree centigrade

6. HPHT method is used for dyeing

(a) Cotton

(b) Wool

(c) Polyester

(d) Silk

7. For dyeing of delicate fabrics machine is used.

(a) Jigger

(b) Winch

(c) Calendering

(d) Star Frame Dyeing Machine

8. Vat dyes are characterized by

(a) Fastness to light

(b) Fastness to rubbing

(c) Fastness to perspiration

(d) Fastness to light, rubbing and perspiration

9. The fibre length offine wools ranges from.

(a) 10–20 cm

(b) 20-25 cm

(c) 3.8-10 cm

(d) 2-5 cm

10. At higher temperature is low.

(a) Air permeability

(b) Drapeability

(c) Tenacity and stiffness

(d) Abrasion resistance

11. Plasticity is opposite to

(a) Tensile Stress

(b) Tensile Strain

(c) Toughness

(d) Elasticity

12. Wool fibres show recovery from an extension of 35%.

(a) 20%

(b) 10%

(c) 60%

(d) 20%

13. The bending and twisting offibre influences of fabrics.

(a) Abrasion resistance

(b) Drape and handle

(c) Warmth

(d) Elasticity

14. Piano feed regulating motion is used in

(a) Scutcher

(b) Card

(c) Draw frame

(d) Ring frame

15. Cages are considered as

(a) Minor cleaning points

(b) Major cleaning points

(c) Beaters

(d) Neps removers

Textile Technology – 2014

PART — 1 :

** Each question carries one mark. 50×1=50

1. Minor cleaning points in blow room are

(A) Openers

(B) Beaters

(C) Lattices

(D) Cages

2. Trash to lint ratio in blow room waste is

(A) 70 : 30

(B) 90 : 10

(C) 80 : 20

(D) 60 : 40

3. The cylinder speed in comber is expressed in

(A) NPM

(B) RPM

(C) mts/min

(D) mm/min

4. Fibre to fibre separation is achieved in

(A) Draw frame

(B) Comber

(C) Card

(D) Speed frame

5. Combing reduces neps by

(A) 50%

(B) 70%

(C) 80%

(D) 25 -— 40%

6. Step cleaner consists of

(A) 6 – 8 cylinders

(B) 14 cylinders

(C) 20 cylinders

(D) 24 cylinders

7. Repco spinning produces

(A) Core spun yarns

(B) Self twist yarns

(C) Cover spun yarns

(D) Siro yarns

8. Cone angle required to wind knit cones on drum winding machine is

(A) 20 15

(B) 30 10

(C) 200 15

(D) 90 15

9. The stretch allowed for cotton warp on multicylinder sizing machine is

(A) 5%

(B) 2%

(C) 6%

(D) 10%

10. The air pressure required on Air — jet loom at the time of weft insertion is

(A) 10 bar

(B) 6 bar

(C) 20 bar

(D) 30 bar